Revolutionizing Production: Introduction:

In the ever-evolving landscape of manufacturing, businesses are constantly seeking innovative solutions to streamline production processes and meet the increasing demands of consumers. One such groundbreaking development is the advent of On Demand Manufacturing Service, a paradigm shift that has transformed traditional manufacturing approaches. In this article, we will delve into the significance of On-Demand Manufacturing Services, with a particular focus on their impact on plastic injection molding—an integral aspect of modern manufacturing.

Understanding On-Demand Manufacturing Services:

On-Demand Manufacturing Services refer to a dynamic and flexible approach to production that allows businesses to efficiently scale their operations based on current demand. This model stands in stark contrast to traditional mass production methods, offering companies the ability to produce goods in smaller quantities, tailored to specific requirements. This adaptability not only reduces waste but also facilitates a more responsive and agile manufacturing ecosystem.

Plastic Injection Molding: A Cornerstone of Modern Manufacturing:

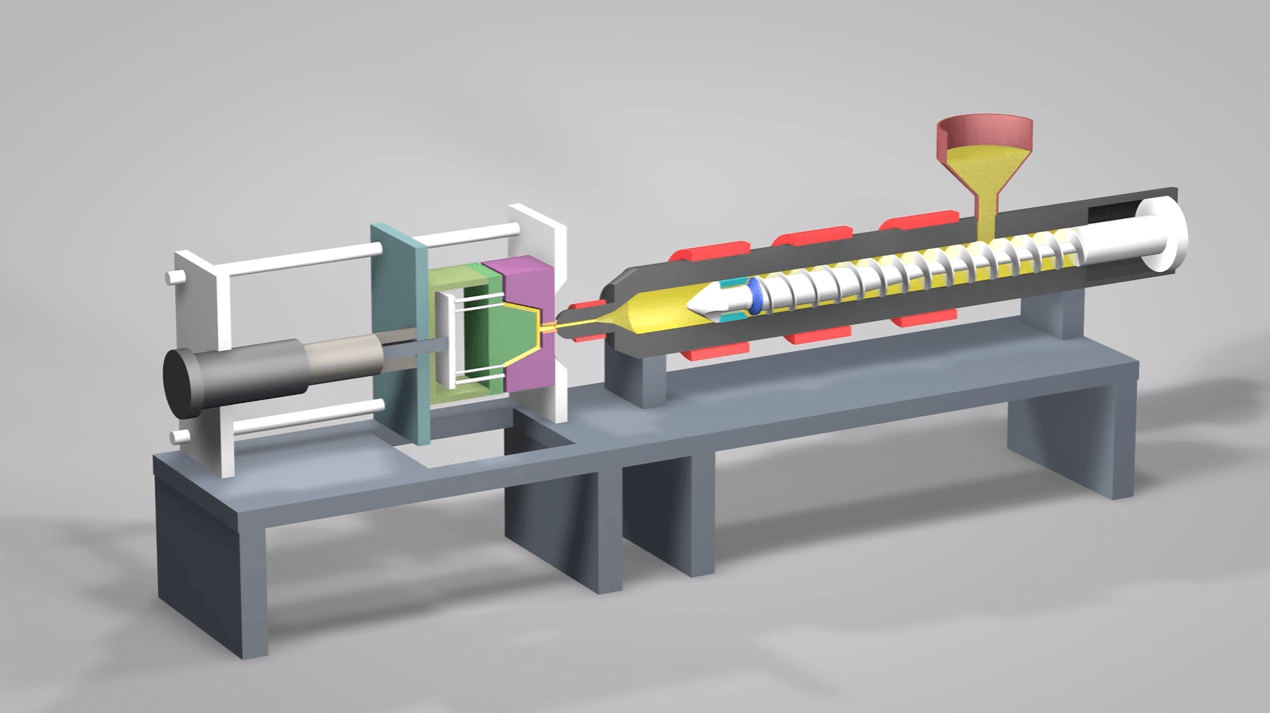

Plastic injection molding is a widely adopted manufacturing process that involves injecting molten plastic into a mold cavity to create a wide array of products. From intricate components for the automotive industry to consumer goods like toys and packaging materials, plastic injection molding plays a pivotal role in the production of diverse items. The process is known for its efficiency, precision, and cost-effectiveness, making it a preferred choice for manufacturers across various sectors.

The Challenge: Traditional Approaches vs. On-Demand Manufacturing:

While plastic injection molding has proven its efficacy, traditional manufacturing approaches often pose challenges related to economies of scale. Mass production requires substantial upfront investments in molds and tooling, limiting the flexibility to adjust production volumes based on market demands. This is where On-Demand Manufacturing Services step in to revolutionize the landscape.

Advantages of On-Demand Manufacturing in Plastic Injection Molding:

- Cost Efficiency: On-Demand Manufacturing Services mitigate the need for large-scale investments in molds and tooling. This cost-effective approach allows businesses to avoid excess inventory, reducing overhead costs associated with storage and management.

- Flexibility in Production: The ability to adjust production volumes in response to market fluctuations is a game-changer. On-Demand Manufacturing enables plastic injection molding manufacturers to scale up or down as needed, ensuring optimal resource utilization and responsiveness to changing market dynamics.

- Reduced Lead Times: Traditional manufacturing can involve long lead times due to the time required for tooling and setup. On-Demand Manufacturing, on the other hand, minimizes lead times, accelerating the transition from design to finished product.

- Customization and Prototyping: On-Demand Manufacturing Services empower businesses to explore customization without the constraints of mass production. Prototyping becomes more accessible, allowing for iterative design processes and faster product development cycles.

- Minimized Waste: Mass production often leads to overproduction and excess inventory, contributing to environmental waste. On-Demand Manufacturing Services support a just-in-time production model, minimizing waste and promoting sustainability.

The Role of On-Demand Manufacturing Companies:

As the demand for flexible manufacturing solutions grows, numerous On-Demand Manufacturing companies have emerged to cater to the specific needs of plastic injection moulding companies. These companies act as facilitators, connecting businesses with a network of manufacturing partners equipped with the expertise and capacity to fulfill orders on demand.

Collaborating with On-Demand Manufacturing Companies:

To leverage the benefits of On-Demand Manufacturing in plastic injection molding, businesses can collaborate with specialized service providers. These collaborations offer access to a diverse range of manufacturing capabilities, ensuring that the production process aligns with the unique requirements of each project.

Choosing the Right On-Demand Manufacturing Partner:

- Expertise in Plastic Injection Molding: Selecting a partner with expertise in plastic injection molding is crucial. This ensures that the manufacturing process is optimized for efficiency, quality, and precision.

- Technological Capabilities: An effective On-Demand Manufacturing partner should leverage cutting-edge technologies in plastic injection molding. This includes the use of advanced materials, innovative mold designs, and automation to enhance overall production capabilities.

- Scalability: The ability to scale production volumes according to demand is a defining feature of On-Demand Manufacturing. Choosing a partner with scalable operations ensures that businesses can adapt to changing market conditions seamlessly.

- Quality Assurance: Quality control is paramount in plastic injection molding. A reliable On-Demand Manufacturing partner should have stringent quality assurance processes in place, including inspections and testing protocols to guarantee the integrity of the final products.

Conclusion:

On-Demand Manufacturing Services are reshaping the future of plastic injection molding and, by extension, the broader manufacturing landscape. The shift towards flexibility, cost efficiency, and reduced lead times is empowering businesses to thrive in an era of rapid technological advancements and dynamic market demands. As the demand for customized, sustainable, and on-demand production continues to grow, the collaboration between plastic injection molding manufacturers and On-Demand Manufacturing Services is poised to drive innovation and redefine the possibilities of modern manufacturing.