In modern industrial applications, ensuring a stable, uninterrupted gas supply is essential. Whether it’s for semiconductor manufacturing, pharmaceutical labs, or medical devices, the need for clean, reliable, and precise gas delivery is paramount. The Gas Changeover System, Ultra High Purity Gas Regulators, and Jewellok Stainless Steel Pressure Regulator work together to deliver high-performance gas management systems that are crucial for operations that demand consistency and purity.

What is a Gas Changeover System?

A Gas Changeover System is an automated mechanism designed to ensure that a continuous gas supply is maintained by switching from one cylinder to another when the first cylinder is depleted. This system is particularly valuable in settings where a steady flow of gas is critical, such as in research labs, industrial manufacturing, and welding applications.

Without an automated system, gas supply disruptions can cause delays, halt production, or lead to inaccuracies in sensitive processes. The Gas Changeover System detects the drop in pressure in a cylinder and instantly switches to a full one, preventing any interruption. This technology improves safety by reducing human error during cylinder exchanges and minimizes the risk of leaks during manual handling.

Why Purity Matters: Ultra High Purity Gas Regulators

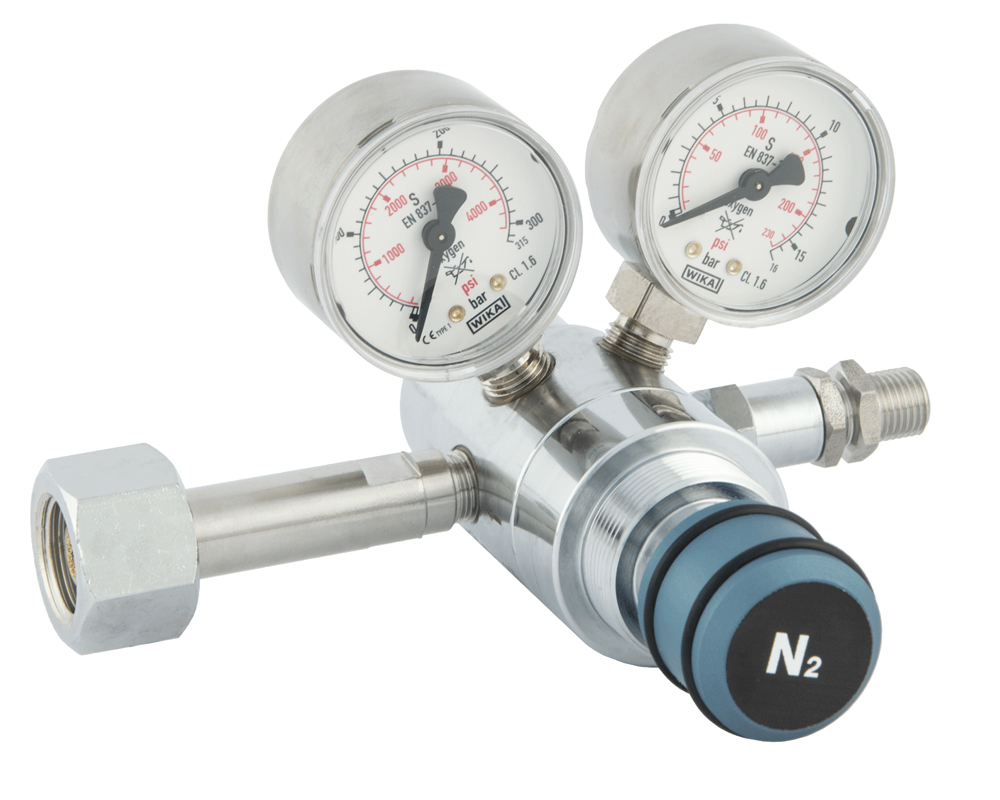

When dealing with specialty gases—such as those used in the semiconductor, pharmaceutical, and aerospace industries—purity is of the utmost importance. Ultra High Purity Gas Regulators are designed to ensure that gases remain free from contamination, which is essential for processes that rely on precise gas compositions.

These regulators are engineered with electropolished stainless steel bodies, which provide a smooth, clean surface to prevent contaminants like moisture or particulate matter from entering the gas supply. The use of metal-to-metal seals in these regulators eliminates the risk of contamination through traditional rubber or elastomer seals that can deteriorate over time.

Furthermore, Ultra High Purity Gas Regulators are crucial for maintaining consistent pressure in systems where even minor fluctuations could affect the outcome of sensitive experiments or production processes. In environments like gas chromatography or medical gas systems, stable pressure and high-purity gas are necessary to ensure accuracy and safety.

Jewellok Stainless Steel Pressure Regulator: Reliability in Demanding Environments

The Jewellok Stainless Steel Pressure Regulator is engineered for environments where durability, precision, and corrosion resistance are critical. Stainless steel construction ensures that the regulator can withstand harsh conditions, such as exposure to aggressive gases, high pressures, and temperature variations.

Jewellok regulators are built for precision, maintaining a consistent output pressure even when faced with fluctuating inlet pressures. This feature makes them ideal for applications like industrial manufacturing, gas welding, and any system that requires steady, reliable gas delivery. These regulators are particularly valued in industries where high-pressure or corrosive gases are handled.

In addition to strength, the Jewellok regulator also incorporates advanced sealing technology, which prevents leaks and ensures safe operation. Whether in chemical processing or in a research facility dealing with high-purity gases, the Jewellok regulator delivers stable pressure and consistent flow, all while ensuring safety and minimizing maintenance.

Seamless Integration: How These Systems Work Together

The integration of a Gas Changeover System, Ultra High Purity Gas Regulators, and the Jewellok Stainless Steel Pressure Regulator forms a complete, highly efficient gas management solution. These components work synergistically to ensure that gas is delivered continuously, at the correct pressure, and without contamination.

The Gas Changeover System ensures there is no interruption in gas flow by switching between cylinders automatically. As the gas enters the regulator, the Ultra High Purity Gas Regulator ensures the gas remains uncontaminated and maintains the desired pressure level. The Jewellok Stainless Steel Pressure Regulator finally ensures that the gas is delivered at a stable pressure to downstream systems or equipment.

By using all three systems together, industries can avoid disruptions, maintain purity standards, and ensure the safety of their operations. This seamless flow from cylinder to regulator to application is critical for sensitive industries like semiconductor fabrication, medical gas delivery, and high-precision research.

Choosing the Right Gas Management System for Your Needs

When selecting a gas management system, it’s important to consider the type of gases you’re working with, the required pressure control, and the level of purity needed. Ultra High Purity Gas Regulators are necessary if you need to prevent contamination and maintain gas integrity, especially in laboratory or high-tech manufacturing environments. For high-pressure applications or industries handling aggressive or corrosive gases, the Jewellok Stainless Steel Pressure Regulator is an ideal choice due to its durability and precision.

If your process involves frequent cylinder changes or large-scale gas use, a Gas Changeover System will help maintain continuous supply and improve operational efficiency. Understanding the specific demands of your operations, such as cylinder size, gas type, and pressure range, will help guide the selection of the right components.

Conclusion: The Future of Gas Handling Systems

As industries continue to evolve and demand greater precision, reliability, and purity in gas delivery, the Gas Changeover System, Ultra High Purity Gas Regulators, and Jewellok Stainless Steel Pressure Regulator represent the future of gas management technology. By integrating these advanced systems, industries can ensure that their gas supply remains uninterrupted, uncontaminated, and precisely regulated.

These technologies are not just improving efficiency but are also driving safety and productivity in sectors that rely on high-quality gas management. Whether you’re working in a laboratory, a manufacturing facility, or a medical environment, these advanced solutions provide the stability and performance that today’s demanding industries require.